Just about 4 months ago Tesla officially announced acquisition of SolarCity – click . Many people consider this as a giant leap towards bringing solar energy to the masses. Today we finally have a real-life case study of Tesla’s revolutionary solar system in use and it’s undeniable that Elon Musk’s company is on the right track to lead the solar energy revolution.

This week, a well-known consumer advocacy portal CHOICE – click, published an article describing the story of an Australian Tesla fan who used the Powerwall battery for the past year and experienced its saving potential.

Powerwall – click is a smart lithium-ion energy storage pack designed and produced by Tesla Inc. In short, this product is a battery pack for your home that stores energy from photovoltaic panels and delivers sustainable electricity, even when the sun isn’t shining. Powerwall is a great backup power device but it also gives the user the ability to sell excess of energy back to the grid. With its power management system, Powerwall is able to significantly decrease household energy bills spending.

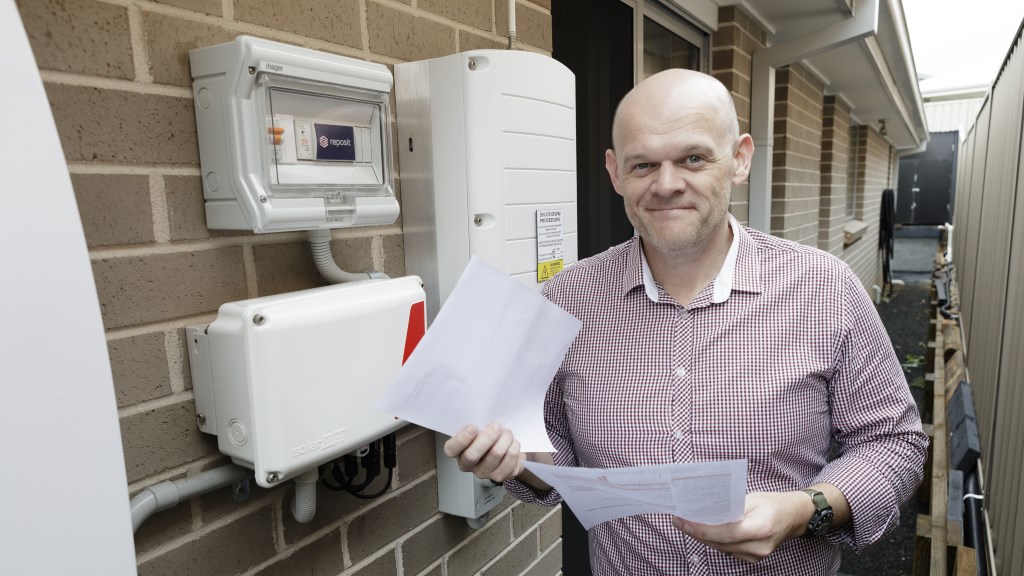

The best proof for Tesla’s solar system cost cutting capabilities is the story of Nick Pfitzner described in CHOICE article – click. Nick lives with his family in a four-bedroom home in Kellyville Ridge, Australia. This large residence is equipped with atelier, laundry, outdoor entertainment area and its own pool. Powering this home with electricity in 2015 cost Nick $2289 but in January 2015 Nick decided to invest in sustainable energy system. Nick invested $16,790 in buying 7kW Powerwall battery, a 5kWp solar array, a SolarEdge inverter and a Reposit monitoring system.

Nick Pftitzner standing alongside his home solar system

After implementation of this system Nick’s average quarterly bill dropped from $572 in 2015 to $45 in 2016. After a year of using his new power system Nick was able to save 92% on his annual electricity expenses. His annual electricity bill has dropped from $2110 in 2015 to $178.71 in 2016. This level of efficiency surprised the owner himself: “Before I crunched the numbers I was looking at what would be my return on investment. If it saved me 80% of my power bill, [I thought] it would be pretty good,” he says. Outstanding efficiency of Nick’s system topped original Tesla Inc projections estimating that their solar systems can pay itself off within 14 to 18 years. If Nick’s solar system will continue operating at this rate it will payback in just 8 years.

Isn’t it marvelous?

Remarkable results of Nick’s power system will undoubtedly ignite already booming market of solar power systems. This combined with Tesla’s progressing plan of building 3 more Gigafactiories – click in order to increase supply and lower costs of batteries and photovoltaic panels only amplifies the strong belief that solar will power our future.

Sources:

https://en.wikipedia.org/wiki/Tesla_Powerwall