Eating meat is a way of life for many people. Meat is considered essential source of protein and contains many other nutrients. But it is also known that the breeding of poultry and cattle is inefficient and requires a huge amount of resources. Huge areas, water and fodder for livestock are given to pastures. In addition, cattle breeding harms the atmosphere. At the same time, the world’s population is growing relentlessly. Scientists estimate that by 2050 the world’s population will grow from the current 7.7 to 9.7 billion, and by the end of the century it will reach 11 billion people. Naturally, the issue of feeding a growing population becomes more acute.

That is why marketologists and statisticians predict in the coming years the growth of the market for artificial meat from laboratory, which is gaining fame on the wave of interest in responsible consumption. Startups around the world are creating a new industry, promising salvation for the environment without compromises on taste, composition and quality.

I believe humanity is doomed to abandon natural meat and replacement of animal products is becoming a common practice in modern society. Meat substitutes are created using protein synthesis, which involves combining amino acids to form a new type of protein. Scientists have come a long way in creating realistic substitutes for vegetable and animal protein. However, the future of meat synthesis is still unknown.

From my perspective, the best way to create realistic meat substitutes is biotechnology. Scientists are learning to synthesize different types of proteins from plants. But there is one problem: the production of a high-quality analogue of meat, which has the same taste and qualities, is now too expensive. But recently, a team of scientists from Singapore and China has made a breakthrough in this area. They have found a way to use food waste to grow meat, reducing production costs and helping to make cultured meat a potential food option for people in the future.

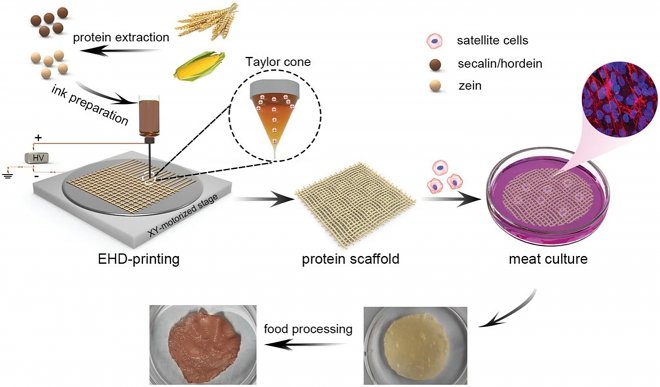

Muscle cells multiply easily and vigorously in nutrient media, but need a wireframe to give them a characteristic shape to become meat. Without it, the meat will most likely resemble a lump of mashed potatoes. Unique wireframes can be created using new 3D printing technology. However, it is difficult and expensive, as it requires the use of food and safe neutral substances. The use of collagen or gelatin destroys the idea of sprouts because they are extracted from the flesh of living organisms, and edible polymers are too expensive. Finding cost-effective edible ink for printing is one of the major challenges in the production of cultured meat.

In search of an alternative, scientists paid attention to agricultural waste in the form of barley and rye husks. Modern technologies make it possible to extract proteins, which, after processing, can be turned into the basis of “ink” for 3D printers and scaled to create the same framework for the growth of muscle tissue.This technology allows more efficient processing of products and significantly reduces the need for animal husbandry.

I believe that this method of printing using such ink has great potential for future meat synthesis. The husk that remains from the grains is not suitable for food and in fact it is thrown away. This is a cheap resource that can be used quite successfully. I believe that the ideal option in the future may be further development in this area, finding new sources that can serve as a framework for growing stem cells. This creates less harm to nature, reduces greenhouse gas emissions, since no animal dies for this food source, which is more ethical. In addition, this type of meat synthesis can help produce meat faster than traditional methods.

In conclusion, the idea of scientists pushed me to another idea: the way to our survival is the reuse and recycling of resources. In any field, whether it is the production of synthetic meat or any other. We are now at a stage of development where we can no longer be mere consumers and only take resources from nature, but must find and use other ways to meet our needs.

https://phys.org/news/2022-12-3d-printing-ink-cultured-meat-cost-effective.html

Демографические изменения | Организация Объединенных Наций (un.org)