Introduction.

In the contemporary world, the influence of computer games is so profound that it has become an integral part of the lives of many young people. Games like Pacman, GTA (Grand Theft Auto), Mortal Kombat, Angry Birds, and countless others have not only captivated individual players but have also left an indelible mark on human pop culture. Their impact extends beyond the digital realm, inspiring films, fashion, and even humor. Gaming consoles such as PlayStation, Nintendo, and Xbox are coveted possessions, serving as gateways for teenagers to immerse themselves in the captivating world of games.

Over the past 50 years, from the introduction of the first games to the present day, the gaming landscape has evolved from a simple yet satisfying pastime to an entirely new realm of exploration, as exemplified by the likes of the Polish game Cyberpunk 2077. The rapid evolution of games raises pertinent questions about their influence on humanity. Are games a potential danger to the real world, or is this gaming revolution moving in a positive direction that should alleviate concerns?

To explore these questions, this essay will delve into the advantages and disadvantages associated with playing computer games and utilizing gaming consoles. By examining both sides of the coin, we aim to provide a comprehensive understanding of the impact of computer games on individuals and society.

What computer games give the world?

- Happiness.

Happiness is a prominent benefit that computer games offer, catering to a fundamental desire shared by many. Engaging in video games often leads to a profound sense of joy, particularly when achieving success in various gaming scenarios. Whether conquering an e-sport match or mastering a game on its most challenging difficulty level, the exhilarating rush of victory is a common experience for gamers. However, the spectrum of happiness in gaming is broad and diverse. Beyond competitive triumphs, individuals find joy in exploring virtual worlds, immersing themselves in compelling narratives, or enjoying collaborative gameplay with friends. What makes gaming a unique source of happiness is its ability to cater to individual preferences, offering a personalized and fulfilling experience to players of diverse tastes.

- Technology development.

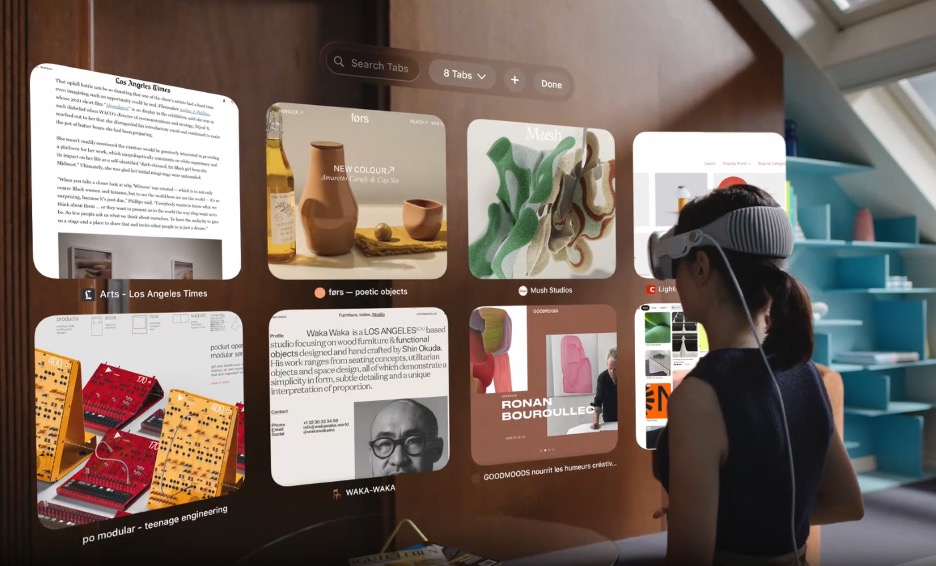

Technological development plays a pivotal role in the gaming industry, directly influencing the quality of games. An exemplary contributor to this arena is NVIDIA, a renowned company recognized for its production of graphics processing units (GPUs). These GPUs are instrumental in game creation, as NVIDIA collaborates closely with game developers to integrate their games seamlessly with the innovative GPUs provided to computers. Currently holding the position as the leading supplier of GPU technology for computers, NVIDIA consistently refines its technology year after year. Noteworthy advancements, such as the introduction of real-time ray tracing (RTX) and Deep Learning Super Sampling (DLSS), underscore NVIDIA’s commitment to enhancing the gaming experience. These innovations not only bring about incredible graphics but also contribute to a more immersive and enjoyable gameplay environment. The company’s dedication to pushing technological boundaries signifies its role as a key player in shaping the future of gaming aesthetics and performance.

- Economic Growth.

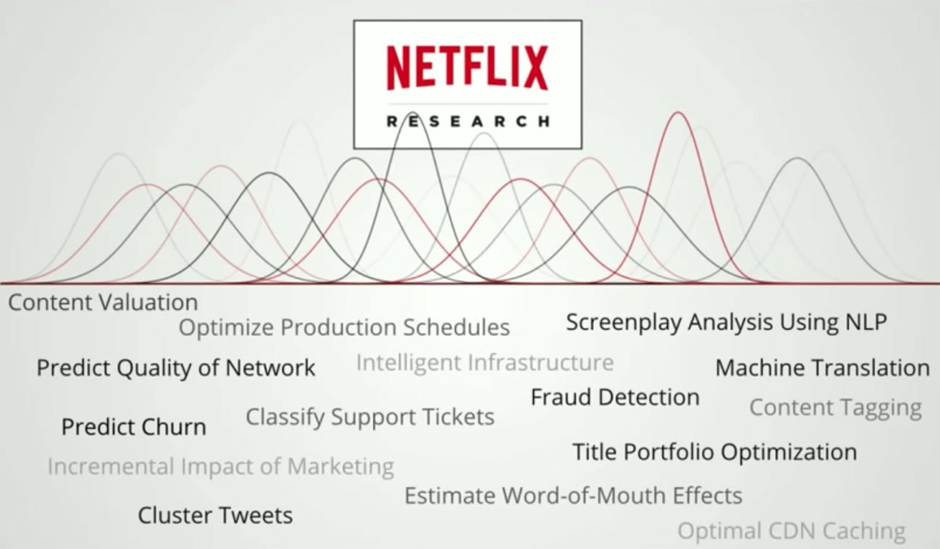

The gaming industry is experiencing unprecedented growth, with each passing year witnessing the addition of new job opportunities. The demand for highly skilled specialists is on the rise as the industry strives to create increasingly sophisticated and innovative games. In response to this demand, new game companies are emerging, aiming to introduce fresh offerings to the market. Larger businesses are expanding their operations, attracting top talent to maintain their competitive edge.

Games themselves have become highly sought-after commodities with a consistent and high demand. Whether purchased from online shops or traditional electronic stores, computer games are a daily indulgence for enthusiasts worldwide. Consoles like the PlayStation 5, crafted by Sony, exemplify this trend, selling in tremendous quantities globally and yielding substantial profits. In a bid to match Sony’s success, Microsoft entered the race with the Xbox One, illustrating the intense competition among major brands in the market.

The flourishing e-sports industry further underscores the industry’s dynamic nature. The creation of more e-sports teams, the participation of a growing number of e-sports players and increased corporate interest in supporting them mark significant developments. Platforms like Twitch, dedicated to streaming gaming content, have become thriving communities where streamers and audiences share a common passion and support one another.

This remarkable growth in the gaming sector has substantial implications for the economy. Predictions suggest that without the contributions of the gaming industry, the economic landscape would be notably different. As we witness the continual evolution of this industry, its impact on various facets of our society becomes increasingly profound.

Why computer games are bad for humans?

- Addiction.

While games initially bring joy, the pursuit of happiness through gaming can transform into a perilous cycle of addiction. Players often lose track of time immersed in matches or tackling higher difficulty levels, gradually surrendering control over their gaming habits. Initially, they believe they can play at will, but eventually, gaming becomes an all-consuming activity, overshadowing relationships with family, friends, and even a sense of responsibility.

The allure of enhanced technology in game production, coupled with more captivating games and consoles, intensifies the addictive nature of gaming. The emotions evoked by these features can be so compelling that individuals succumb to the temptation to play rather than engage in meaningful conversations with their loved ones. Consequently, gaming addiction contributes to a rise in antisocial behavior, with individuals opting to spend entire nights in front of a computer screen rather than participating in social gatherings or romantic endeavors.

Moreover, the ubiquitous availability of computer games exacerbates the problem, making it challenging to combat addiction. The ease with which games can be obtained further amplifies the issue, leading to potentially devastating outcomes in both societal and personal realms. Addressing this phenomenon requires a concerted effort to manage and regulate access to games, as well as promoting awareness about the potential consequences of excessive gaming on mental health and relationships.

- Impact on Physical Health.

Computer games can take a toll on physical health, manifesting themselves in various ways. Firstly, prolonged hours spent in front of a computer screen, especially during nighttime without adequate lighting, can significantly impact eyesight. This habit can lead to deteriorating vision over the long term.

Secondly, an improperly arranged gaming setup can result in spinal issues. Remaining seated in an armchair for extended periods can cause severe back pain, and maintaining a hunched position during gameplay may contribute to developing a hunchback over time.

Lastly, gaming itself is not conducive to maintaining a healthy physical condition. The sedentary nature of prolonged gaming sessions can lead to weight gain and overall weakened physical condition. Those aspiring to achieve a fit and athletic body must be cautious not to spend excessive hours in front of a monitor.

- Impact on Academic/Job Performance.

One significant drawback of computer games is the time they consume, time that could otherwise be invested in enhancing academic or job performance. The allure of computer-generated fun often proves more enticing than studying for school exams or delving into educational materials. In the contemporary setting, interactive computer games have become the preferred choice for unwinding after a demanding day at school or work.

However, this preference becomes problematic when the need for focused study or knowledge enhancement takes a backseat to gaming. Frequent prioritization of games over academic pursuits can swiftly lead to a decline in school performance. Staying up all night gaming, for instance, not only induces fatigue but can also result in reduced attentiveness during classes, hindering the learning process.

The more one indulges in gaming, the greater the potential impact on academic performance, particularly since many computer games do not contribute to essential subjects like math, English, or biology. Instead, they primarily offer entertainment, which, while enjoyable, may not be conducive to success in exams or job performance.

Conclusion.

Inarguably, computer games have reshaped our world, contributing to modern technology, fostering economic growth, and offering unparalleled moments of joy and experiences. However, this technological advancement comes with a double-edged sword – the emergence of addiction.

The increasing prevalence of game overuse, particularly among the younger population, raises concerns. Excessive gaming not only poses physical health risks but also diminishes academic and job performance. The allure of games, while providing happiness and memorable experiences, has the potential to overshadow real-world responsibilities.

These drawbacks serve as a crucial warning. It is imperative for society to address the negative consequences of gaming addiction. Striking a balance between the digital and real world is essential to prevent the proliferation of problems associated with computer games and consoles. The quest for more games should be tempered with a commitment to mitigating the potential adverse effects.

Ultimately, maintaining equilibrium between the virtual and tangible realms is vital for the survival and prosperity of the real world. By addressing the challenges posed by excessive gaming, we can harness the positive aspects of computer games while preserving the well-being of individuals and the broader community.

My opinion.

I think that computer games are really amazing entertainment. I like playing them in my free time or spending time with my friends playing matches in League of Legends games. Nevertheless, I am trying to not play when I have important tasks do to like, for example exams, homework or learning to develop my knowledge. Nowadays, I have an opinion that there are more interesting and of course real things in real life than the digital world of computer games. I believe that people will see and understand that computer games are just and only entertainment, and they are not important as family or duties. Let me know what your thoughts about computer games are.

AI Engine:

- Microsoft Bing.

Articles about computer games addiction:

- https://my.clevelandclinic.org/health/diseases/23124-video-game-addiction

- https://www.ncbi.nlm.nih.gov/pmc/articles/PMC10065366/

- https://www.webmd.com/mental-health/addiction/video-game-addiction

Article about gaming industry:

- https://builtin.com/gaming

Thank for reading this article about computer games. I hope that you enjoyed reading it :).